Not known Incorrect Statements About Conway Concrete Company Conway Arkansas

The Best Guide To Concrete Driveway

Table of ContentsConcrete Contractor - An OverviewHow Conway Concrete Company Concrete Foundation can Save You Time, Stress, and Money.How Conway Concrete Company Concrete Patio can Save You Time, Stress, and Money.Get This Report on Concrete Contractor

:max_bytes(150000):strip_icc()/difference-between-cement-concrete-and-mortar-2130884-final-ac-5c1aa0e546e0fb0001909553-fd07f31197cd491e85bf0eb8200f6f5e.png)

consist of properly generated video clips instructed by exercising craftspeople, as well as auxiliary downloads like quizzes, plans, and various other materials to help you understand the abilities.

Concrete is solid inside and also beautiful exterior. Concrete is a composite building material made by integrating cement (generally Rose city concrete), water, crude accumulations, and great aggregates.

Exactly how many types of concrete remain in usage? This post will certainly aid you select the sort of concrete that is right for your building and construction job. The background of concrete returns to 6500 BC when the Nabataea investors in the areas of Syria and also Jordan built the first concrete-like structures.

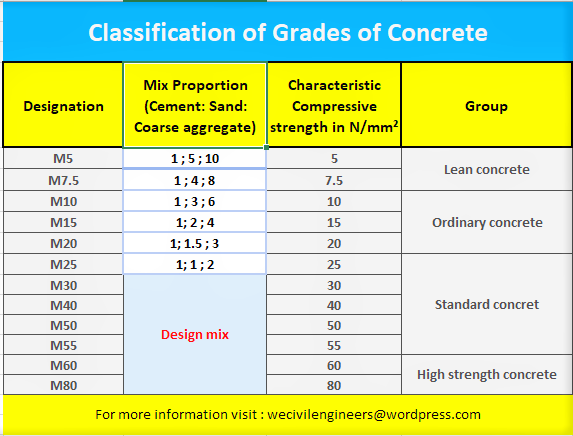

In civil engineering, the use of concrete as an architectural product is prevalent and also well recognized for the worth provided by concrete and its adaptability of applications. A criterion (typical concrete) concrete mix ratio is 1:2:4: 1 part cement 2 components sand 4 parts aggregates The above materials are combined to form a stone-like paste that hardens gradually as well as awaits usage in different structures (Conway Concrete Company concrete contractor).

Conway Concrete Company Concrete Slab Things To Know Before You Get This

In some cases, auxiliary cementitious materials (SCMs) are contributed to concrete blends for crucial benefits like decreased leaks in the structure and also the general hardening of concrete. As an example, fly ash concrete is recognized to be a more powerful concrete with enhanced sturdiness. Let's start with one of the most common sorts of concrete used in construction: Likewise called "normal concrete," plain concrete is utilized with a mix proportion of 1:2:4 of cement, sand, as well as aggregates.

Normal strength concrete is a fast-setting compound of aggregates, concrete, and water. Absence of tensile stamina makes typical toughness concrete appropriate for buildings or pavements that do not need high tensile toughness. Like plain concrete, normal strength concrete contains comparable ingredients but varies in toughness with 10-40 MPa. Casting concrete right into a recyclable mold or kind produces precast concrete that is cured in a regulated environment to obtain the preferred stamina.

An additional vital aspect is the proportioning of the cornerstones to ensure that the concrete holds various other participants in location. Healed precast concrete is transferred to building and construction sites for developing total precast structures, such as floorings and wall surfaces. Precast concrete structures are set up using cranes and special hooks are offered to lift them.

Prestressed concrete is industrially developed concrete that entails placing bars or ligaments at the ends of an architectural unit before the application of concrete. The system goes through compression tensions throughout manufacturing to attain a higher architectural load ability as well as boosted toughness and tensile strength. Prestressed concrete units provide faster construction and also are commonly made use of for greatly loaded structures, such as bridges and also roofings.

The Basic Principles Of Concrete Company

When currently produced specialty concrete mixtures are offered, they simply have actually to be poured at building and construction sites. Contrary to on-site concrete blending, all set mix concrete provides high precision as well as reduces worksite complication. Admixtures like retarders are needed to protect all set mix concrete for use at building sites as well far from the factories that produce and also mix the concrete.

As the mix embeds in 20-40 mins, it works well for jobs like a fence, mailbox blog post, a small concrete slab, or any type of other building and construction job that needs rapid-setting concrete. Fiber-reinforced concrete is instilled with macrofibers or microfibers to make it last much longer in harsh climate condition like incredibly cold winters months.

Self-leveling concrete is appropriate for projects that call for flat, smooth surface areas. Enhanced concrete is a composite building material strengthened Click This Link with steel bars put in the formwork throughout building and construction. Examples of such bars consist of upreared steel cages and also steel rebars. After the kinds prepare, concrete is poured and vibrated to ensure both products mix well.

Known as "cellular concrete" and "flowable concrete," light-weight concrete is made from various accumulations, such as clays, pumice, shales, as well as a fantastic read scoria. This easy-to-pour, self-leveling concrete with reduced thermal conductivity is made use of for fabricating frameworks, such as flooring slabs, long-spanning bridge decks, as well as window panels. Light-weight concrete is additionally made use of for protecting steel frameworks as well as is made making use of light aggregates, consisting of: Increased clay, increased shale, and synthetic shale.

How Conway Concrete Company Concrete Foundation can Save You Time, Stress, and Money.

Understood as "absorptive concrete," pervious concrete's layout allows for 15% to 20% gaps Our site of the quantity of concrete. As pervious concrete is excellent for the passage of water, it is used in the building and construction of driveways and sidewalks to recharge groundwater and fix drain problems.

Stamped concrete obtains its name from stamping or putting a type of mold on top of the hardening concrete to attain a decorative concrete finish. The surface finish imitates the look as well as feel of natural brick, ceramic tile, as well as stone surface areas, to name a few. As soon as the floor has hardened, it is usually sealed to boost the long life of the concrete mixture.

Air-entrained concrete is concrete in which air is entrained (instilled) with the addition of a lathering agent such as foam or gas. The outcome is concrete with billions of microscopic air cells per cubic foot, with the entrained air comprising 3% to 6% of the concrete. This technique gives better resistance to concrete against abrasion, degeneration because of freezing as well as thawing, and also scaling.

Usual air-entraining agents include fatty alcohols, fatty acids, as well as resins. Asphalt is a dark mineral that includes a mixture of hydrocarbons called "asphalts." Conversely referred to as "asphalt" or "blacktop," asphalt concrete is the concrete of option for pavement work and tasks, such as airport paths, freeways, car parking lots, roadways, and sidewalks.